Realising that all timber will move regardless of the species and environment can be an unpleasant surprise. But as the expression goes, forewarned is forearmed. Understanding why timber moves and how is crucial when working with and specifying timber.

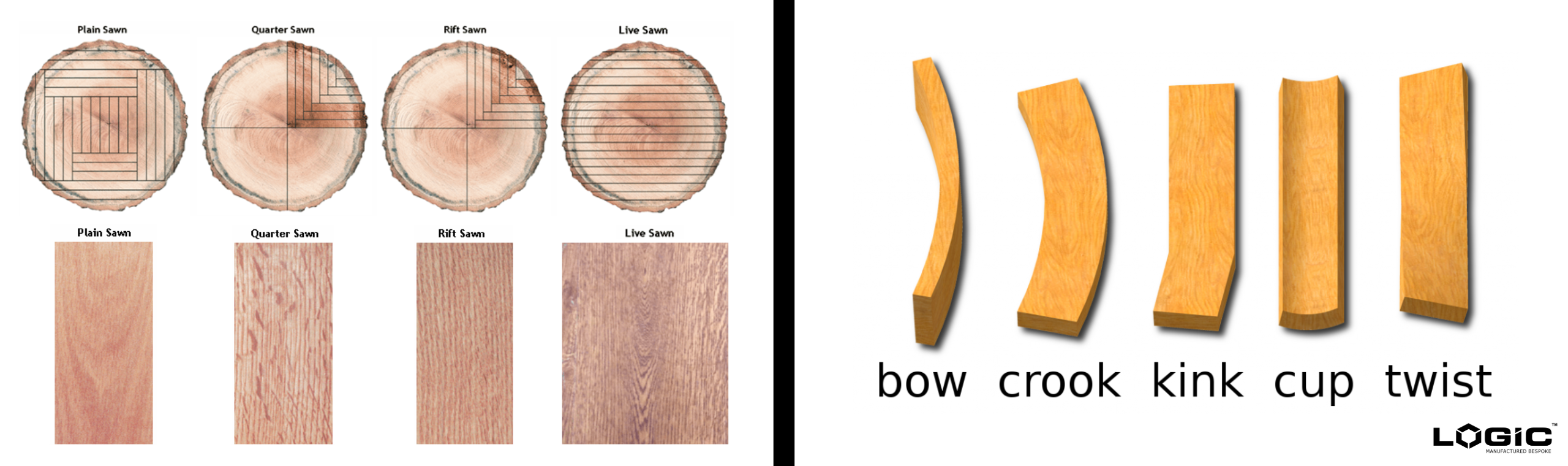

Timber movement, or warping, is where the timber is curved in some plane because of uneven shrinkage or expansion. It usually affects planks and smaller sections of timber, although larger profiles can be affected as well. Movement is an umbrella term for a range of specific movements. The below list describes these in more detail:

Timber is a ‘hygroscopic’ material, meaning it absorbs and releases moisture until it reaches equilibrium with its environment. This continuous exchange of moisture occurs through the process of diffusion, driven by differences in air moisture content. When an area with higher moisture levels is exposed to an area with lower moisture, moisture transfers until balance is achieved.

The concept of ‘equilibrium moisture content’ (EMC) is pivotal. EMC signifies when timber’s moisture content aligns with the surrounding atmosphere’s humidity.

At a fundamental level, wood fibres expand as they absorb moisture and contract as they release it, causing the timber to expand and contract. In the northern hemisphere, humidity increases in summer and decreases in winter.

As a rule of thumb, timber can change in size by 1% for every 4% shift in moisture content levels.

When freshly felled, timber may have over 50% moisture content, while UK summer humidity hovers around 15%. The resulting adjustment can be substantial.

Warping occurs due to uneven moisture changes. Factors include faster drying of outer areas and grain direction.

The primary cause of visible warping is the transition from freshsawn to seasoned timber. Even after this phase, seasonal changes continue, although they may not be noticeable for external furniture.

Timber’s length remains relatively stable compared to width and height, as changes mostly occur across the grain’s width.

Species: Different timber species vary in their warping tendencies. Tropical hardwoods like Opepe & Iroko tend to resist warping due to lower initial moisture content and straight grain patterns. Hardwoods are generally more resistant than softwoods.

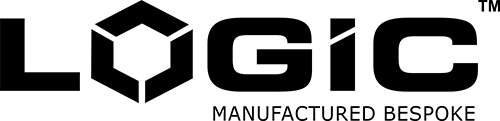

Cutting Method: Flat sawing is common and cost-effective, but it causes more movement. Quarter-sawn and rift-sawn timber resist warping better but are less efficient and more expensive.

Sapwood vs. Heartwood: Sapwood, the outer section of a trunk, is more prone to warping than heartwood due to its rapid moisture fluctuations.

Profile Size: Larger timber sections (end profile over 150mm square) are less prone to warping because grain patterns tend to cancel each other out. Smaller sections (end profile less than 80mm square) are more susceptible.

Grain Patterns: Timber with straight, close-grain patterns tends to be more stable. Hardwoods often exhibit this feature due to their slower growth and denser growth rings.

Manufactured Materials: Plywood and MDF hardly warp compared to solid timber, with minimal, negligible movement.

https://en.wikipedia.org/wiki/Wood_warping

https://www.kaltimber.com/blog/2017/2/6/equilibrium-moisture-content-who-why-when-how

https://woodworking.stackexchange.com/questions/5871/which-direction-does-wood-expand

https://www.thisiscarpentry.com/2010/09/03/moisture-content-wood-movement/

https://workshopcompanion.com/KnowHow/Design/Nature_of_Wood/2_Wood_Movement/2_Wood_Movement.htm

https://www.logic-sf.co.uk/blog/2018/02/timber-how-the-moisture-content-effects-it/

https://logic-bespoke.com/fresh-sawn-vs-seasoned-timber-stability-vs-availability/

https://homeguides.sfgate.com/stable-wood-against-warping-shrinking-99470.html

https://www.hunker.com/13401288/which-wood-warps-the-least

https://growitbuildit.com/how-to-buy-lumber-that-is-stable-and-doesnt-warp/