Reducing CO2 Emissions in Soft Landscaping

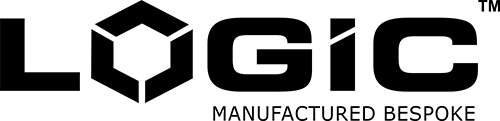

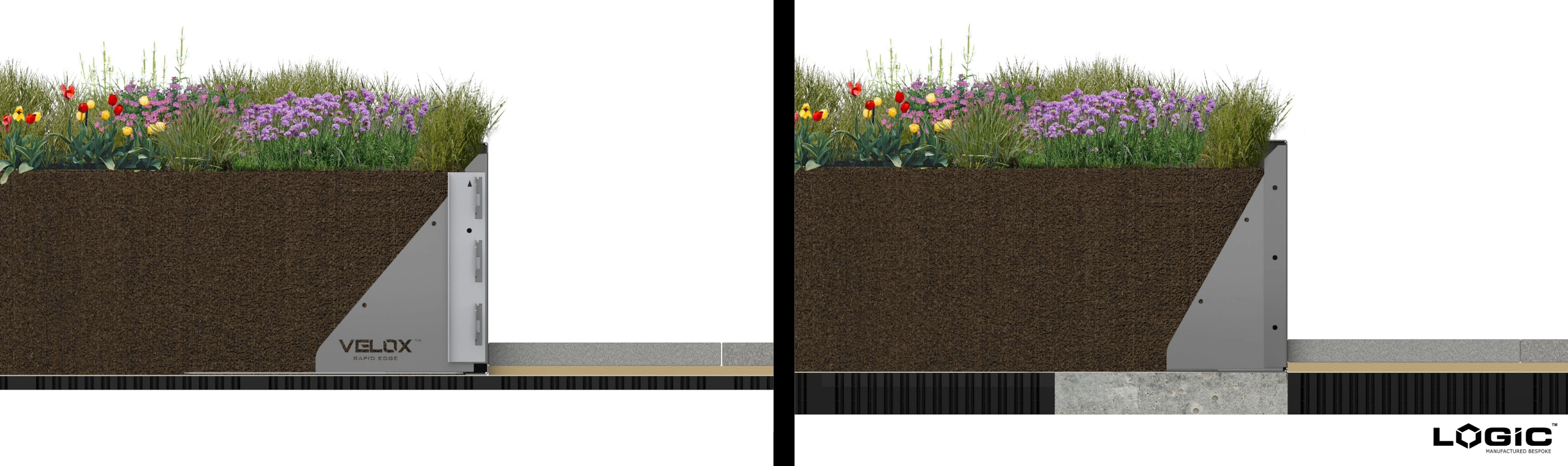

Concrete, often hidden behind the scenes, plays a significant role in soft landscaping. For instance, every meter of planter edging, whether on a rooftop garden or at ground level, typically requires around 110 kilograms of concrete for its foundations, with the planter edge bolted onto these foundations.

To put it in perspective, an average urban soft landscaping project featuring approximately 500 linear meters of planter edging can consume a staggering 56.5 tonnes of concrete for the foundations alone.

However, the environmental impact of this reliance on concrete is concerning. The production of concrete, specifically its primary component, cement, is known for its significant carbon footprint. In fact, manufacturing 56.5 tonnes of cement results in a staggering 44 tonnes of CO2 emissions (with 1 tonne of cement contributing 780 kilograms of CO2 emissions). Additionally, cement production carries other adverse environmental effects, including habitat destruction, raw material requirements, and dust pollution.

The Environmental Impact of Concrete

Concrete, although indispensable in construction, has severe environmental consequences. It’s responsible for 5-8% of global annual CO2 emissions, making it the third-largest human-made emitter after transport and energy generation.

CO2 emissions are just one aspect; the environmental toll of quarrying for raw materials is equally concerning. Sand extraction, driven by high demand, often leads to environmental violations and associated criminal activities.

Furthermore, cement production consumes a significant portion of the world’s industrial water use, contributing to water scarcity concerns.

In conclusion, while soft landscaping relies heavily on concrete, it’s vital to explore sustainable alternatives to mitigate its environmental impact and reduce CO2 emissions.

A simple change in the planter system can drastically reduce CO2 in a building. This all contributes to sustainability commitments and BREEAM ratings.

By using a Self-weighted system or Raised Floor System, the concrete required for other systems is eliminated. Apart from the obvious cost benefits, the carbon emissions hidden in this concrete are dramatic and should be considered.

The example project mentioned above with 500m linear metres of planter edging, there is the potential to save 56.5 tonnes of cement, reducing the carbon impact of the building by 44 tonnes.

Although this is relatively small when considering the entire concrete volume of a building, it all adds up. It is through schemes and innovations like the Velox Rapid Edge that energy consumption created by cement production has been reduced by approximately 30% since the 1970s in the EU.

Understanding Cement Production

Concrete’s environmental impact is largely attributed to the production of its main ingredient: cement.

Cement manufacturing is a complex process that begins with the mining of minerals such as limestone, leading to large-scale environmental problems like vehicle pollution and landscape degradation. These minerals are then finely ground into a powder known as raw meal.

This raw meal undergoes a high-temperature treatment in a rotating kiln, where chemical bonds break and reform into new compounds. Unfortunately, this process contributes significantly to carbon emissions in two ways: burning fossil fuels to heat the kiln and the emission of CO2 as the chemical bonds in the raw meal break down under heat. In scientific terms, this is represented as ‘thermal decomposition’: CaCO3 (Limestone) + Heat = CaO (Lime) + CO2.

Afterwards, the clinker, small nodules about 3-4 cm in diameter, is ground into a fine powder and mixed with gypsum to create cement.

https://www.greenspec.co.uk/building-design/environmental-impacts-of-concrete/

https://en.wikipedia.org/wiki/Cement

https://www.cemex.co.uk/cement-production-process.aspx